Overview

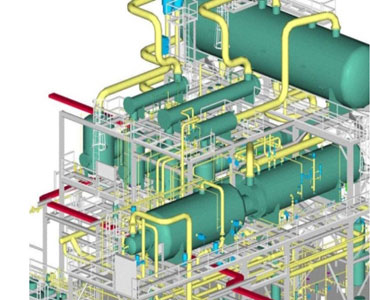

Techno Futura can rapidly respond to requirements for Pipe Spool fabrication by means of taking a flexible approach to fabrication and works closely with the engineer/ end user to meet any specific pipe spool delivery priorities. We can design, fabricate, test, certify and upgrade piping to meet the standards such as ASME B31.1, B31.3 & B31.8.

We have the capacity to handle large contracts for piping, piping assembly and pipe spool fabrication. Shop pre-fabrication of pipe spools is a proven means for reducing field installation costs while providing the highest of quality in the products fabricated.

VARIETY OF PRE-FABRICATED PIPE SPOOLS:

- Process Plant Piping

- Gas and Steam Turbine Piping

- Compressor Piping

- Cooling water & Lube oil Piping

- Turbine Integral Piping

- Boiler Integral Piping

DESIGN CAPABILITIES

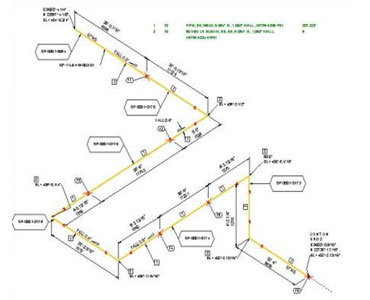

- Solid Works drawings of each individual spool to assure error free fabrication and prevention of production delays.

- Most Fabricated Pipe Spool orders start with Isometric piping layout drawings furnished by customers. We have the capability of analyzing piping systems utilizing Coade’s Caesar II Pipe Stress Analysis software.

MATERIAL SOURCING:

We have well researched database of suppliers who are prequalified with major oil & gas customers, from whom we can source all type of materials required for piping.

FABRICATION:

- We employ automatic cutting, automatic beveling & fabrication of piping systems as well as post weld heat treatment as required for your projects.

- We have developed and qualified the welding procedures for all types of steels such as carbon steel, stainless steel, duplex stainless steel, high strength low alloy steel, inconel, hastelloy etc. under the guidance and supervision of our metallurgical, mechanical and welding engineers.

- We implement continual improvement program with a motto to achieve “Zero Repair” on our welding that has been enthusiastically endorsed by all of our Welding Team.

- The program emphasizes control of all welding processes to approved welding procedures and assuring the highest quality and consistent welding results.

TESTING & COATING:

We have high pressure testing infrastructure including pressure pumps, manifolds and test instruments. We have a fully developed paint yard to provide the painting / coating services for the piping spools.